There’s a wide variety of lighting solutions that you can consider for your warehouse, but choosing the most suitable option can be pretty challenging, especially if you wish to cut down on energy costs.

As a warehouse owner or operator, you need to know and understand these details to create the best environment, especially if there is no natural light around your warehouse. In this guide to warehousing lighting, we will:

- Discuss warehouse lighting fixtures

- Consider how these fixtures can help your business and warehouse management

- The best practices while choosing the fixtures, and more.

The Basics of a Warehouse Lighting System

Before we get into detail about warehouse lighting systems, let’s discuss some basics and how they can assist you in saving money.

There are several factors to consider for warehouse lighting, which we will discuss in detail. Let’s discuss why investing in an efficient warehouse lighting system is important.

- Lesser Maintenance Costs

Setting up a warehouse is only a part of the job and, frankly, an easier one compared to the maintenance of these warehouses. The warehouses are deeply connected to business operations and can be a serious overhead expense for business owners.

Warehouses operate all year long, even in extreme temperatures. Therefore, taking care of warehouse maintenance can help reduce energy wastage, decrease energy consumption, and reduce energy usage per square foot distribution.

- Improves Productivity

The lighting in your warehouse also impacts your productivity, maneuvering, product handling, and light flickering. Traditional lighting can often face flickering, which induces headaches, nausea, and other complications.

The right LED lighting system can help reduce distractions in the warehouse and help the warehouse owners optimize their production.

The improved productivity contributes to the overall functionality of the business and helps them grow. With the right electricity system, creating a productive work environment becomes easier.

- Reduced Energy Costs

The average energy consumption in a warehouse in the United States is 6.1 kilowatt-hours ( kWh), which makes operating them quite costly. The costs impact the profit margin for warehouse operators and business owners, which is why energy consumption matters.

The right warehouse setting, high bay lighting, assessment of light output, and inclusion of direct light can help reduce costs once you focus on illuminating the dark areas, adding occupancy sensors, and choosing proper lighting options.

- Improved Ambiance and Warehouse Safety

There are numerous LED lighting fixture options for warehouses. You can turn lights in the right direction and improve the overall look of your warehouse.

The optimal warehouse ambiance ensures you can avoid lumen depreciation and power surges, get the lowest initial cost, and increase the life span of your warehouse fixtures.

It’s best for long night shifts, and since these lights can adjust their brightness as needed, it provides slow brightness transition.

- Utilizing Frequent Switching

Minimizing Operational costs is the main aim of any warehouse operator. With smart LED lighting systems, it’s easier for warehouse operators to reduce energy consumption as needed.

Most of these lights come with built-in sensors that detect movements in tall shelving units and adjust lighting faster. They can also turn on and off depending on how quickly the transition is needed while lighting large spaces.

This makes lighting warehouses becomes easier as various light range emits different results. The right utilization of the new warehouse lighting made fixtures more useful.

Types of Warehouse Lights

While creating the best lighting design for your warehouses, you need to choose the right warehouse lights. Before you can move on to choosing the right warehouse lighting, you should understand the various types available.

You’ll know the variety of lights available in the market and can make the right decision accordingly. It’s a smart approach to assist you in setting up the warehouse lighting for maximum lumen output. Let’s have a look.

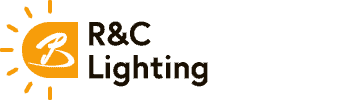

1, Tube Lights

The industry’s first and most common type of warehouse light is tube lights. These lights are best for installation in specific areas and mounting at the right ceiling heights (8 to 10 feet). They are available in multiple varieties that you can choose from:

- Type C Tubes: Work with an external driver.

- Type B Tubes: Work via bypassing the ballast.

- Type AB Tubes: Can work with or without the ballast.

- Type A Tubes: Work with the existing ballast.

The added versatility of these tube lights makes them an ideal option for full illumination in several areas. These include:

- Warehouse office spaces

- Breakrooms

- Storage areas

These tube lights usually come in standard lengths of 2′, 4′, or 8′, depending on your needs.

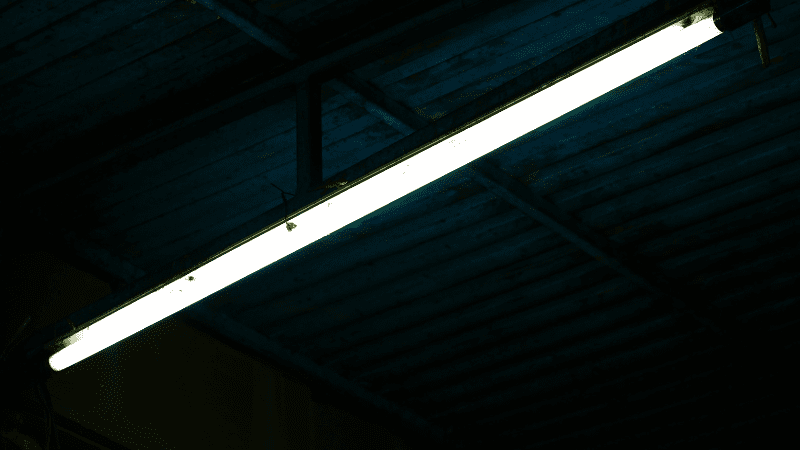

2, High Bay Lights

The high bay lights are best for warehouses with high ceilings. The high ceiling length ranges between 20 to 45 feet and shares direct light with the floor. It’s crucial to note that the higher the illumination you need, the more lumen output you should consider. Due to their versatile applications, high bay lights also have various designs. These include:

Round High Bay Lights

Round high bay lights provide the warehouse with a wide beam spread, covering large areas with light. These areas can increase visibility within the warehouse area. Since these round high bay lights have one contact point, they’re simpler and easier to install.

Linear High Bay Lights

The linear high bay lights have a tighter, rectangular light distribution that features shelving areas or specific aisles. The areas these lights can be on may be:

- Surface

- Suspended

- Pendant-mounted, etc.

These lights are best suited for the narrow light pattern without circular or square distribution. Most professionals utilize these lights in giant warehouses, airport hangers, manufacturing plants, and amphitheaters.

You can easily find these bay lights in different sizes, ranging from 10″ to 13″ in diameter (round). Or you may also find them 2′, 4′, or 8′ in length (linearly)

Note that if the warehouse ceiling is under 20 feet in height, the low bay lights can provide the same results in your smaller area.

This simple trick can help you create the perfect LED lighting design and equal light distribution with the light source of your choice.

3. Wall Pack Lights

Wall pack lights are box-shaped light fixtures that are wall-mounted, typically to the outside of a building, to provide lighting for vehicles and pedestrians. Below are the different styles of wall packs and when to use them.

- Traditional Wall Pack Lights

Wall-pack traditional lights have a wider beam spread and are best suited for entryways where you need extra lighting for maximum control.

The higher lumen output of these traditional wall pack lights makes them best for warehouse applications.

- Full Cut-Off Wall Pack Lights

Full-cut-off wall-pack lights are best for skylights and can help prevent pollution.

- Slim Wall Pack

The slim wall pack has an adjustable beam angle that increases light projection.

Most professionals use these kinds of lighting in utility sheds, loading docks, storage areas, and walkways.

These standard wall pack lights range from 6″ to 18″ in length, depending on the style.

4. Troffer Lights

Troffer lights, also called drop-ceiling lights, are a clean-line option ideal for indoor spaces that need powerful, recessed lighting. Most of these lights fit a T-bar grid ceiling and have a slim, low-profile design.

You will also find a diffuser or reflector to create the best lighting effect. These lights provide direct and indirect light build-up for better visual results.

All sorts of interior areas have these lights installed. However, some of the most common ones include the following:

• Healthcare facilities

• Offices

• Retail spaces

• Schools and others.

These lights have different Troffer light sizes, including:

- 1′ x 4′

- 2′ x 2′

- 2′ x 4′

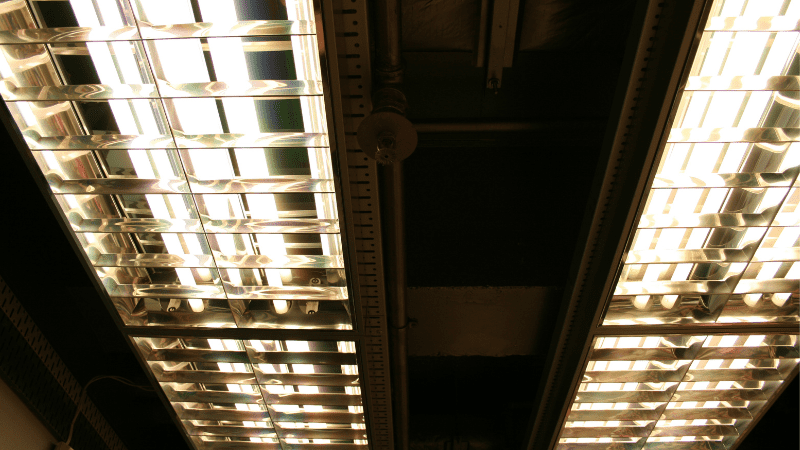

Industrial Strip Lights

industrial strip lighting is a more commercially-used warehouse light. The light has a reputation for an amazing light pattern. However, special features like a low profile design and a small footprint make the industrial strip lights ideal for small-sized building applications.

These lights in ceiling-mounted designs create a clean look and can help utilize the building’s height correctly. Due to their variety of applications, selecting warehouse lighting becomes easier. You can find the industrial strip lights in the following:

- Storage and utility area

- Retail location

- Factory floors

- Stairwells

- Hallways

How to Choose the Right Warehouse Light Fixtures

The choice of warehouse light fixtures can greatly impact the final look of your warehouse and your experience with the lighting systems at the end. There are a variety of LED lights depending on the light fixture design and features.

Therefore, warehouse owners and managers must consider these factors before choosing their next warehouse lighting system.

- Brightness

The light bulb’s lumens determine these light bulbs’ total brightness potential. The more lumens a bulb has, the more lighting it can produce in the longer run.

For example, metal halide lamps produce bright lights thanks to their long warm-up time. It’s best for warehouse managers to look at the lumen output instead of the wattage while choosing the right bulbs for their needs.

As a rule of thumb, remember the larger the warehouse area, the more lumens are needed.

- Energy Efficient Lights

The energy consumption of the warehouse lights impacts the total cost of operations. Therefore, you will find the warehouse professionals adding LED lights that are more efficient.

Many of these lights also have sensors that can help reduce the overuse of LED lights. You can get high-intensity discharge and save on the cost of these LED lights. The energy-efficient lights are more suitable against power surges, which can make these lights go off for up to fifteen minutes.

- Burn time or Life Span

Warehouse units require consistent operations, which require longer-lasting light bulbs. The average light expectancy of the commercial light fixture is between 8,000 to 10,000+ hours but can change depending on the exact bulb type.

Nonetheless, warehouse owners should always install light bulbs with a higher burn time to reduce the chances of maintenance and its requirements.

- Color Temperature

The color temperature is professionally counted in the Kelvin Scale. Thus, it shows the color hue created by a light bulb. A light fixture with a color temperature between 3000K and 5000K is considered a benchmark for most warehouse applications.

However, choosing a bulb with a lower Kelvin of 3000K produces a warmer yellow color. Similarly, installing a higher Kelvin light bulb emits a cooler, crisp white color. However, others might have a bluish tint to them. Similarly, high-pressure sodium lamps produce a warmer-looking light.

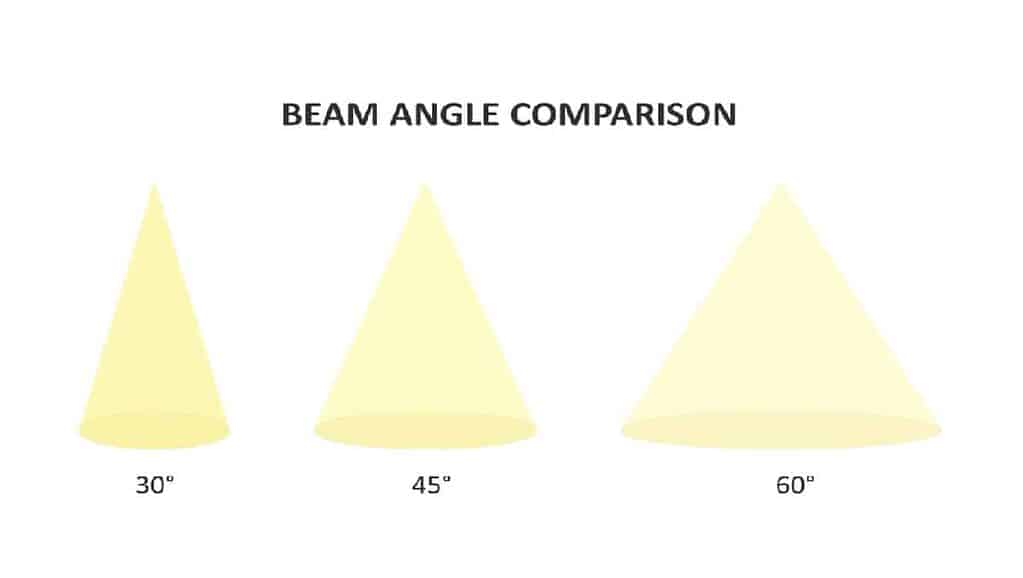

- Beam Angle

The light fixture’s beam angle determines if it’s suitable for your desired warehouse locations. For example, the light fixtures installed on an open warehouse floor should provide maximum illumination. On average, the beam angle between 90 to 120 degrees is considered good for closed indoor areas like warehouses.

On the other hand, the HID lamp with a higher cooldown period provides sufficient light and is an energy-efficient choice. The narrower light types are more suitable for a more focused distribution throughout the warehouse.

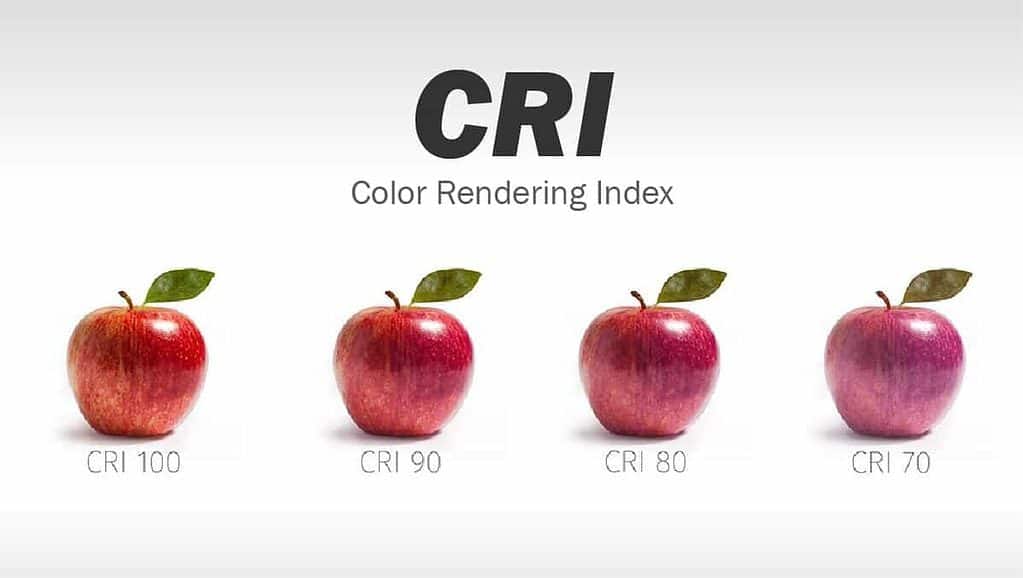

- CRI Rating

The Color Rending Index (CRI) rating is another crucial consideration when choosing light bulbs for your warehouses. The CRI rating ensures the light color contrasts properly throughout the area.

The CRI rating also shows the potential of the light you install to replicate natural light. The more efficient a light bulb is in this way, the more suitable it is for indoor spaces like warehouses.

- Dimmable

The constant possibility of dimmable lights within the surroundings increases the energy efficiency of the light bulbs you install in the warehouse. These lights stay on through most of the day, which can seriously impact your HID systems that require warm-up time.

The lower lumen output means reduced power surges and a cool white light around your warehouse.

Benefits of LED Lights over Fluorescent Lights

- Omnidirectional light

Fluorescent bulbs create an omnidirectional light, while LEDs have a directional light beam, which impacts the final light results.

- No Need for Reflectors

Fluorescent bulbs radiate light 360 degrees in the circumference of the tube. Because of this design, only a small section of the total light gets shared Downard (in the case of a desk in an office). The rest of the light moves to less functional areas unless these lights have reflectors, which scatter a big part of the light. The LED lights are directional with a 110-degree arc. Therefore, they don’t need reflectors.

- Higher Energy Efficiency

LED lighting is more energy-efficient than fluorescent bulbs. as per the U.S. Department of Energy, a 12-watt LED light is equivalent to a 15-watt fluorescent light, making it 20% more efficient in power consumption

- No Ultraviolet Light

Fluorescent bulbs emit UV light, which harms the eyes and can damage the fabric. However, LED light does not have UV lighting, as all of its light is in the visible region of the eye.

- Longer Life Span

LED lights last up to 13 times longer than fluorescent lighting, which means more savings in maintenance costs.

- Better Safety

LED light is more damage resistant than the fragile tubes of fluorescent lights. and are safe even if they break. However, fluorescent bulbs have mercury, which can cause more damage.

Installation and Maintenance of Warehouse Lights: What you should Remember

Maintaining your warehouse units plays a vital role in the overall functions of your business. It’s not sufficient to install the light fixtures and let them operate for years without proper maintenance. However, some tips can help make the maintenance and installation process easier.

1. Check bulbs

burnt out, loose, or poorly performing fixtures are some of the most common problems with commercial lighting. Therefore, a lighting layout, brightness, and visibility are needed.

2. Use the Right Replacement Lamps

Replacing the light fixtures timely is another crucial step in your warehouse system. Therefore, you should use light to ensure the lamp is right for the fixture consisting of pins, connectors, or base.

3. Annually Clean Fixtures

Annual light fixture cleanings are a smart way to ensure your systems don’t require extensive care. You can clean the light fixtures and remove any dist and grim that may have collected over time. Once you do all of this, your light fixtures should perform better than usual.

4. Check Performance Characteristics

The performance of your life fixtures plays a vital role in the overall warehouse performance you find. Therefore, you should check the following regularly.

ballasts

drivers

or transformers to make sure there are no problems. If there are any issues, now is the time to remedy them with replacements.

5. Check dimming pre-sets annually

Most dimmers use a pre-set factor. This pre-set should be checked annually to ensure the fixture performs as needed. The time pre-sets usually come in a standard setting depending on the type of dimmers you have installed. We recommend taking the time to resolve these issues and then finding the best one for your needs.

Conclusion

Maintaining warehouse lighting is relatively more challenging when it’s your first time with these kinds of tasks. However, the process becomes easier considering the factors in this article and following the tips we’ve shared about warehouse lighting maintenance. We recommend taking the time to explore your light fixture options before you upgrade the warehouse lighting.

Looking for a professional lighting supplier? RC Lighting can help you!

It’s understandable if you are tired of finding solutions for your warehouse lighting and can’t find the right options to improve them. Our professionals at RC Lighting are available for you all day long.

We have a team of trained professionals who can help you find the required warehouse lights and assess your requirements accordingly. We also recommend communicating with our experts and resolving all your queries about the warehouse lighting. Contact Us Today!