Glare, dark spots, and hotspots are not only unprofessional looking, but result in failed inspections, customer complaints, and high re-fit costs. Lack of luminance uniformity makes even the most well-balanced building facades look like wreckages because an architectural feature is either hidden in shadows or overpowered by strong, bright spots.

This guide targets lighting designers, architects, contractors, and facility managers who require delivering facade lighting that looks good, works well, and passes inspection the first time.

Let’s explore strategies of luminance uniformity facade lighting.

What is Luminance Uniformity?

Luminance uniformity is actually the ratio of the brightest to the darkest point of a surface in lighting design, which also involves consideration of the color rendering index. The lower the difference, the more homogenous the lighting appears.

Ratios of Standard Uniformity in the Industry

Professional facade lighting projects aim at certain uniformity rates according to the type and usage of the building:

Uniformity Ratio (U0) = Minimum Luminance / Average Luminance

Recommended Targets:

- Commercial / Retail Buildings: U0 at least 0.4 ( good uniformity, brand-appropriate)

- Office Buildings: U0 at least 0.5 (high uniformity, appearance of professionalism)

- Hotels/Hospitality: U0 ≥ 0.4-0.6 (friendly, hospitable)

- Institution/Civic Buildings: U0 at least 0.6 (excellent uniformity, formal)

- Landmark/Iconic Buildings: U0 ≥ 0.3-0.5 (respects more dramatic lighting)

Important Principle: Lighting design software should always be used, and a photometric simulation should be done before buying a work of light. Real-world uniformity cannot be predicted by means of manual calculations.

Poor uniformity can result in reduced brightness, unwanted shadowing, and an overall distracting visual lighting effect, contributing to light pollution.

Factors Affecting Uniformity

Various design and surface issues affect the light dispersion.

Key elements include various lighting effects :

Type of Fixtures: Linear LEDs, floodlights, and grazing lights do not behave the same way.

Beam angle: Narrow beams focus light tightly, while wider beams spread it across a broader area.

Mounting height and distance: Improper mounting will cause beams or shadows.

Wall surface material: Reflective surfaces reflect light, and rough surfaces absorb or scatter light.

Choosing the Right Fixture and Position in Building Facade Lighting Design

Choosing the right facade illumination technique and location involves selecting suitable fixtures.

Fixture Selection

Linear LED lights are best for facade lighting because they spread light smoothly. They use asymmetric optics to cut down on glare (shining in your eyes) and keep the wall evenly lit from top to bottom. Use High-CRI LEDs to make sure the building’s colors and textures look natural and true.

Common Wall Washing Beam Angles

Choosing the appropriate beam angle is very important when it comes to uniformity:

Wall Washing Beam Standards:

Wide Beam (30-60 degrees): Ideal when the surface is smooth (concrete, metal panels, glass).

- Produces a smooth wash from top to bottom.

- Minimizes hotspots

- With high smoothness or reflectivity, use 45-60 degrees.

Medium Beam (20-35 degrees): Universal to most complex texturing facades.

- Brings out a balance and also texture augmentation.

- Applicable to both brick and stone with moderate relief.

- Usual selection of general architectural lighting.

Narrow Beam (10-25degrees): To be used as a graze over rough surfaces.

- Underlines drama and richness.

- Ideally used as a complementary rather than a primary wash

Note: Never use beams less than 20 degrees on extremely rough textures, as they give very heavy shadows and low uniformity.

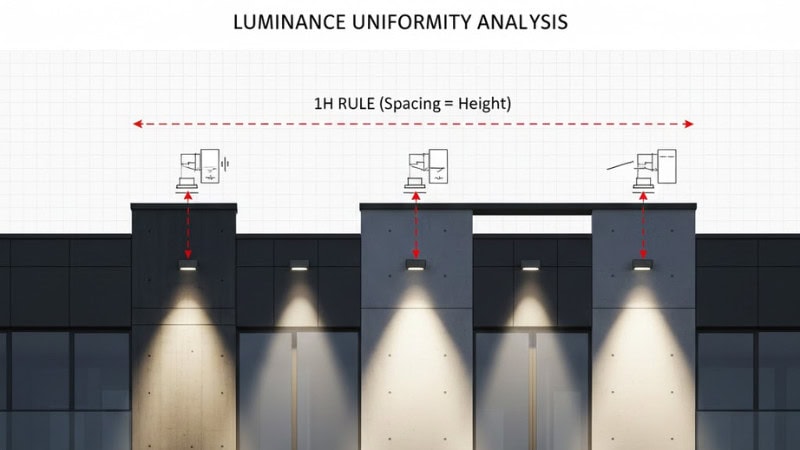

Spacing and Offsetting

To achieve maximum uniformity, apply these established distance formulas:

Fixture Spacing Formula (1H Rule): Spacing = Mounting Height × 1.0

Example: Mounted fixtures should be 3 meters (10 feet) high and spaced 3 meters (10 feet) apart horizontally.

- On textured surfaces: 0.8H to 1.0H distance (even less distant)

- On smooth surfaces: Embody 1.0H to 1.2H distance (may be a bit more distant).

Offset Distance Formula (Wall Distance): Offset = 1/3 to 1/2 of Wall Height

Examples:

- 12-foot (3.6m) wall: Position fixtures 4-6 feet (1.2-1.8m) from the wall.

- 18-foot (5.5m) wall: Fixtures 6-9 feet (1.8-2.7m) wall.

- 30-foot (9m) wall: Have fixtures 10-15 feet (3-4.5m) away.

It is important because excessively close will cause hotspots at the base, and excessively far will cause uneven top-to-bottom coverage. The 1/3-1/2 rule makes sure that there is even distribution of light throughout the wall height.

- Grazing on textured walls: Use the nearer end (1/3 height).

- For smooth flat walls: Take the farther end (1/2 height).

Layered Lighting Structure

A well-designed façade lighting plan uses multiple illumination layers to add depth and visual appeal, taking into account the surrounding environment.

These layers include ambient (for visibility), accent (for features like columns), and feature lighting. These layers, when well combined, make the lighting design seem natural and balanced, especially in large buildings. It also assists in removing distractions occasioned by unequal lighting patterns.

Optimizing the Optical and Lighting Control System

Uniformity is boosted by technical adjustment devices in a significant manner.

Beam Angle and Direction of Light

Beam angle contributes significantly to uniformity control. The wider beam angles (50-60) usually apply to smooth or neutral surfaces where even coverage is needed.

Nevertheless, using textured walls, the slight grazing below 30 degrees will help create the appearance of natural depth. Should the angle be too close or too narrow, however, uniformity may be overpowered by shadows. A mid-range angle maintains texture without emphasizing imperfections or adding drama.

Uniformity is also enhanced with the help of luminaires, optical accessories such as glare shields and light diffusers. Shielding is used to stop the leakage of light, particularly when windows or areas that reflect light are involved. Diffused optics are used to smooth the edges of the beam to prevent outlines on the surface.

Advanced Lens Technology

Recent LED wall washer uniformity equipment has replaceable, adjustable optical lenses for distance, height, or surface finish. In the case of tall buildings, multi-layer optics are applied to make sure that there is no over-illumination in the lower section of the building.

Other systems include rotation-based adjustment for installers during the installation process to manually modify the beam spread.

Smart Control and Zonal Dimming

Luminance can be handled using intelligent lighting control systems according to building zones. If spots appear too lit or dark, adjust dimming levels without moving fixtures.

High-end control techniques are:

- Time-based Dimming at night (to lessen the glare)

- Lux-level view (adjusts to the surrounding ambient lighting)

- Multi-channel drivers (change particular groups of fixtures independently

Smart controls can also be integrated into building management systems (BMS). This allows for controlled brightness on automation. The automation relies on a set sequence, such as facade orientation, season, or event schedule.

Surface Material and Texture Adaptation For Building Façade Lighting

The interaction of different materials with light varies, and the methods of illumination have to change.

Glass reflects the light effectively and can create glare when one is too near the source. Dark colors like matte absorb light, and the intensity of light they receive or the distance needs to be reduced, which can be managed by motion sensors.

Recommended Lighting Parameters for Wall Types

| Wall Material | Recommended Beam Angle | Ideal Offset | Suggested CCT | CCT Application Guide |

|---|---|---|---|---|

| Stone | 15°-30° grazing | Close to the wall (1/3 height) | 2700K-3000K | Warm white enhances natural earth tones |

| Brick | 25°-45° medium | Moderate (1/3 to 1/2 height) | 2700K-3000K | Warm white complements red/brown hues |

| Concrete | 30°-60° wide wash | Standard offset (1/2 height) | 3000K-4000K | Neutral white for a modern aesthetic |

| Glass/Metal | >45° soft wash | Increased distance | 3000K-4000K+ | Cooler temps suit reflective surfaces |

Textured surfaces use slight angle variations to create depth without overshadowing natural features. Facades with smooth surfaces have to be washed regularly to prevent bright and vertical streaks on the walls.

Maintenance and Long-Term Performance

There should be lighting consistency throughout the years, which can be ensured through predictive maintenance. Exposure to environments, aging fixtures, and physical motion may harm performance.

Proactive Maintenance Policy

A proactive maintenance schedule would help in developing a regulated maintenance schedule. It would maintain consistency within lighting systems well beyond the installation date. This generally includes:

- Washing the end of the fixtures and cleaning of the house after every quarter or biannually (depending on pollution/dust levels).

- Recentering of angles and alignment, once a year or after structural maintenance.

- Re-test lumen levels after 2-3-year intervals to determine degradation.

Weather Resistance and Fixture Longevity

Outdoor facade lighting is unprotected from UV radiation, wind, humidity, and temperature variations. IP65 and higher fixtures are suggested where the projects are architectural in nature. Cables and connectors are to be resistant to UV and protect against the intrusion of moisture.

IP Rating Requirements of Outdoor Facades:

- Minimum acceptable: IP65 (dust-tight in the case of water jets)

- Standard to be used: IP66 (additional water protection)

- Harsh Environments: IP67 or IP68 (coastal regions, heavy precipitation, snowy regions)

Depending on the amount of dust or sand, the structures in those areas might need anti-static paint or special types of lenses. These measures could help the structures clean themselves and reduce maintenance needs.

The recent LED systems also have automated diagnostics to indicate power or uniformity problems back to a control panel.

Anticipating LED Aging and Color Variation

The degradation of LEDs is usually inexpensive, with an LED lifetime of 50,000 to 100,000 hours. In multiple fixtures, even slight changes are noticeable. Tight color binning (3 SDCM or less) and using fixtures from the same batch ensure consistent color over time.

Audit of lighting should be carried out after every few years and needs to:

- Compare actual light output with initial light output.

- Check for CCT shift

- Determine any emerging hotspots as a result of surface weathering or body motions.

Seasonal and System Modifications

The direction of the sunlight and the vegetation planting around can influence the lighting behavior as time passes.

This influence is noticeable even near building constructions, where the art of lighting plays a significant role.

It is possible with smart systems to have presets for seasonal variations.

Such systems can automatically adjust the lighting on the façade based on the season, helping to ensure continuity.

Conclusion

Perfect luminance uniformity turns a building facade into a professionally designed one. Even lighting will help your building look clean and tidy, and will highlight all the beautiful building features. Light patterns that are not even, that have distracting hotspots and dark shadows, appear to have poor performance even on the finest buildings.

Systematic planning is the key, just pick fixtures which have an appropriate beam optic, compute the precise interspacing by the 1H rule and 1/3-1/2 offset formulas, adjust beam angles to surface texture, and use intelligent control to adjust installation fine to the installation.

Plan Your Facade Lighting Project with Confidence!

At RC Lighting, we have provided coherent facade lighting to hundreds of commercial, hospitality, and institutional works all over the globe. By merging photometric analysis, selecting custom fixtures, and planning the correct installation positioning, our design team ensures that it shows your building as an exemplary image from all angles in the future, both on the opening night and many years later.

Get a free facade lighting simulation and get a lighting layout, fixture spacing plan, beam angle, and furniture recommendation specific to your building materials and architectural objectives.

Frequently Asked Questions

Q1: What is luminance uniformity in facade lighting?

The ideal ratio of equity of facade lighting is a factor of light 1:3, that is, the brightest should not be more than three times the lightest. This makes the surface appear without excessive contrasts that are formed. Better architectural constructions might strive to achieve 1:2 so that the look is more balanced.

Q2: What is the formula used to calculate fixture spacing?

The quality of spacing between fixtures varies with the beam angle, height of mounting, and the uniformity required. It is common practice that wall washers should be spaced 1 to 1,5 times the distance between the mounting and the wall. Spacing should also be checked through simulation using photometric data (IES files) to obtain correct results.

Q3: Best CCT in various types of buildings?

Hotels typically get the most beautiful at 2700-3000K, and this produces a very warm anticipatory effect. Malls have a good performance of 3000-3500K, which is bright enough and comfortable. The common office colors used include 3500-4000K, which is clean, professional, and neutral.

Q4: How to avoid light pollution?

Installing shielded or louvered fixtures will ensure that light is concentrated in areas that are required. Focus the aim precautionarily not to spill over to the sky, the neighboring buildings, or the streets. Select the right intensities and do not use too wide beam angles on control illumination.