Whether you are new to LED lighting or have been savvy in the field, this article will help you regardless. We will discuss the electrical classes and how LEDs are classified into four categories based on their protection levels. Moreover, this article covers the safety symbols, precautions, and technical guidance in case any mishap occurs, such as short-circuiting, bursting of LEDs, etc.

As we know, LEDs are gaining increasing popularity in the field of lighting. This is because they are energy-efficient and cost-effective. In addition, LEDs’ variety and flexibility in coloring, features, and applications are simply unmatched.

Traditional bulbs such as halogens and incandescent bulbs waste almost 80% of the power in the form of heat dissipation. Since the world is moving towards greener solutions, traditional lighting is becoming obsolete, and rightfully so.

LEDs have certain levels of protection that distinguish their uses and applications. As the number increases from 0 to 3, the protection in LEDs increases and the luminaire is safer to use. Each luminaire belongs to only one of these classes. Let’s dig deeper into the details.

What are IEC Protection Classes?

The IEC protection classes represent how much protection an LED or a luminaire offers to a user from electrical shocks. Generally, a protection or a safety class defines any electronic appliance’s protection level to the individual handling it.

This standard was originally developed by the International Electrotechnical Commission (IEC), an organization responsible for creating and establishing safety standards in electrotechnology.

The protection levels are defined in the standard report IEC 61140. In technical terms, these electrical classes are categorized based on the requirement of the protective earth (PE) connections in the circuitry of a specific appliance.

IEC 60598 sets the protection levels for luminaires specifically. The document provides deep technical insight. However, we will summarize all the categories here, so you don’t have to read the whole document.

The IEC electrical protection classes are mainly divided into four categories:

- Class 0

- Class I

- Class II

- Class III

Generally speaking, if an electronic device is connected directly to the main voltage supply, it must provide level 2 protection. Higher levels ensure the appliance is protected and doesn’t harm the user, even if the 1st level fails.

Class 0

The most basic insulation type is found in Class 0 electronics. This basic insulation relies on only the PVC coating of the wires. Such luminaires don’t have a PE connection, so if the wires are damaged or broken, there’s a high chance of electrocution and bursting. You will not find Class 0 type equipment very easily as they are quite dangerous for the surrounding. There is only a single level of protection between live conductors and metalwork.

Such appliances are extremely rare to find in areas where people live, like households, commercial areas, etc. One tiny mistake can cause a fatal result in the form of electrical shock or explosions and fire. Since the level of protection is low, before any disastrous event, the appliance doesn’t have the feature to sound the alarm and notify the users. No fuses or circuit breakers are involved in such type of protection.

Such appliances are so dangerous that many countries have even prohibited the buying and selling of this electrical class. Furthermore, there is no PE, meaning the appliance’s chassis is not grounded. In other words, if the class 0 appliance fails, there’s nothing available to alleviate the damage except the surrounding environment.

A common example of Class 0 electronic is a 2-pin plug soldering iron (with no earthing) and the “old-style Christmas string lights.”

Class 01

Class 01 is also quite dangerous. In comparison to class 1 appliances, these electronics so allow an earth connection. Without this electrical installation, it would be a class 0 type.

Class I

Class I has an earth wire connection in them. You see three pins, one of which is connected with the earth wire connection of the building. All the metal components in such an appliance are ‘earthed’ and hence protected.

The luminaires designated class I have two protection levels, including basic insulation and the earth wire. Basic insulation includes the plastic insulation of the wires. If there is no earth wire and, for any reason, the wire gets damaged or broken, the user can get an electric shock. The earth connection ‘grounds’ all the conductors and keeps the users safe.

A fuse in the plug or the main fuse box usually protects the user by turning off the connection entirely and sounding an alarm. You will see fuses, RCDs, or MCBs in Class I luminaires that protect users from fatal accidents.

Class 1 electronics have three-pin connections. One is the live wire, the second is the neutral wire, and the third is the ground connection. Also, there’ll be a fuse in the plug. If you see a yellow/green wire in a luminaire, the universal color for the ‘earth wire.’

For luminaires of Class 1, an air gap of 1.5mm and a creepage distance of about 2.5 mm are observed.

Class II

Class II luminaires are composed of two layers of protection. This is why these are known as “double insulated appliances.” These electronics do not require to be earthed. Instead, they are protected using a double layer of insulation material or more often called reinforced protection. The double insulation includes the plastic-coated wires inside and the plastic casing of the luminaire.

Since class II equipment doesn’t have an earth connection, you’ll see a two-pin wire connection; one is a live connection, and the other is neutral.

Such appliances will not fail if only one thing goes wrong. One malfunction will not result in an electric shock to the user. Class II should not be confused with “Class 2” as the latter is a different category unrelated to insulation.

Cell phone chargers are usually designated Class II. Other examples include hair dryers, TVs, photocopiers, etc.

Requirements For a Class II Luminaire

For Class II LEDs that are fixed mounted, an aperture of 3 mm and a creepage distance equal 5 mm.

Class II lights are designed so no wires or electric parts can be directly touched.

The following features in a lamp will make the luminaire a class II type:

- The encasing of the luminaire is made of highly insulating material, such as sturdy plastic, except for metal plates, rivets, etc. Thus, the housing is entirely safe for the users. Moreover, all the electrical components and wires are insulated inside the housing. Such a lamp fixture is called “insulated shell type I.”

- A luminaire that has a sturdy metal housing inside and in which all the parts are double insulated. Such types are called metal housing type II.

- There are Class II luminaires that are a combination of 1 and 2.

- There’s another type called insulated shell type-n, which falls into both reinforced insulation and supplementary insulation.

- Some Class II luminaires have earth connections to help start the luminaire.

- If a class II luminaire having reinforced illumination has a ground contact, it technically has a class I body. In loop installation, such a luminaire may have an “internal terminal block.” These blocks are isolated from the metal parts throughout the class II insulation luminaire.

Class III

Class III luminaires are supplied with power using a special transformer that provides a voltage known as “Separated Extra-low Voltage” (SELV). This safety transformer provides a voltage of 50 V AC or sometimes 24V or 12V. This voltage is so low that a user can come in direct contact without the fear of getting electrocuted in normal conditions. However, this doesn’t mean that you can touch it without safety precautions!

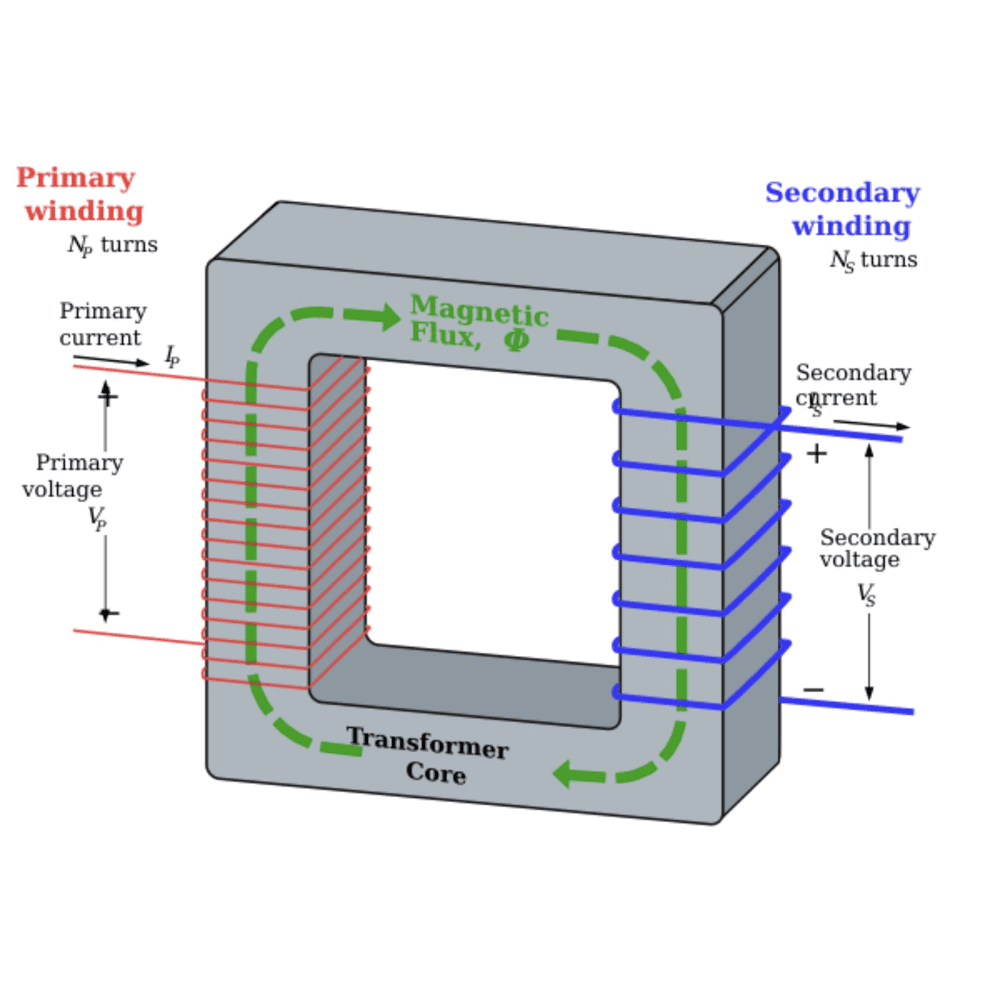

The Isolating Transformer

The transformer that provides low voltage consists of two windings (as shown in the figure). One is called ‘primary winding,’ which is connected to the main power supply. The other is called ‘secondary winding,’ and it is connected to the luminaire.

Both these windings are present opposite to each other in a magnetic core. These windings are isolated and don’t touch, hence the name ‘isolating transformer.’ The voltage is transferred via ‘induction.’ This isolation between the windings provides protection equal to the double insulation in other classes.

There is no need for an earth connection because the safety transformer does all the protection needed. This means that the safety insulations we see in Class I and Class II are not required in Class III, as the transformer does all the job.

LED Strip lights are mostly a Class III product. They usually require a separate low voltage transformer (also known as LED Driver).

Here’s a Catch:

Although class III products are safer than Class II and I, this protection level is still insufficient for some medical applications. There’s always a chance of mishap. For example, a computer is a class III machine. It uses SELV to charge its battery. However, if the battery malfunctions and becomes overheated, there’s a high risk of it bursting. Nothing is 100% safe.

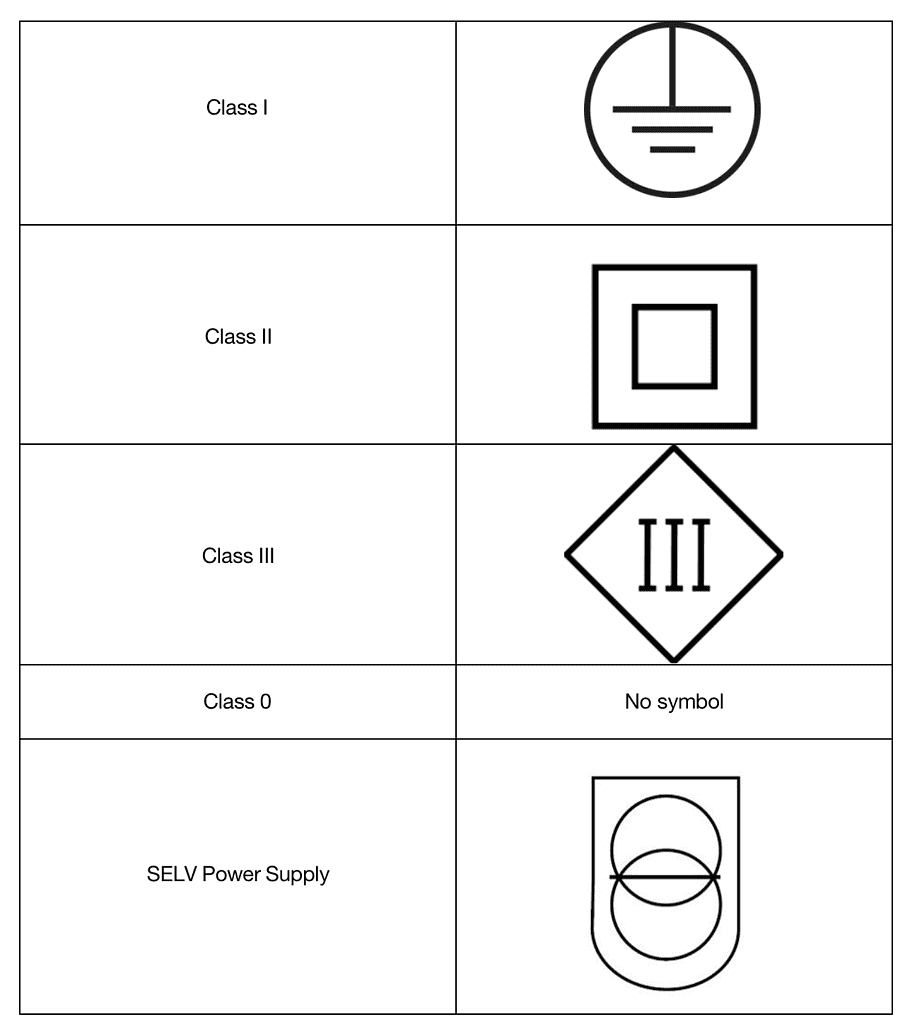

Symbols

Here is a table of the symbols used to designate the classes.

Comparison Of the Classes

We have created a comparison table for you to quickly understand the levels of protection against electric shock for the luminaires.

| Luminaire Class | Protection description | Applications |

| Class I | Class I luminaries have basic insulation as well as grounding protection. Once the basic insulation fails, the grounding protection will stop any kind of mishap. | They are usually seen with a sturdy plastic case, such as street lamps, LED lighting poles, traffic lights, shell lamps, courtyard lamps, etc. These cases increase safety. |

| Class II | This class has supplementary insulation such as reinforced or double insulation, in addition to the basic insulation. | This is the kind of safety insulation found mostly in lamps and fixtures that people can touch more often, such as table lamps, portable LED fixtures, etc. |

| Class III | The fixtures that use the SELV power supply (<50 V) are labeled as Class III. These are highly protected because of the low voltage usage. | A high level of protection is used in areas where children are involved, medical devices, or work environments. |

| Class 0 | The lowest level of protection is based solely on basic insulation. If the wires become naked, the damage is likely to take place. | Chandelier and ceiling lamps come in such categories. These are used in dry environments and dustless places. |

In conclusion, class 0 has the lowest safety. The level of protection increases with the number, and Class III offers the highest level of protection. Countries such as the US have banned the use of class 0 since 1973. However, there are no such restrictions in China. Using luminaires of different classes is calculated by considering the design, position, applications, environment, and installation.

Class III LED luminaires are mainly used in outdoor applications where they have to bear extreme weather conditions. On the other hand, class I and class II lamps can be used mostly indoors, in warehouses and stores, etc.

How To Protect Yourself from Getting Electrocuted?

Realistically speaking, the LEDs are now extremely safe and protected to handle. The only sure-fire way you’ll get electrocuted is by sticking your finger in the socket. You can also get an electric shock if you install or replace the LED lights.

Changing the Bulb

While changing the bulb, you are at a good enough risk of getting an electric shock. The main reason is that you can get the shock if your fixture is turned on and you change the bulbs with your bare hands. The solution is rather simple:

- Make sure the switch is turned off. Double-check if the LED fixture is turned off.

- You can use the circuit breaker.

Turning off the fixture may still put you at risk because the connection may be lost due to voltage surges or bad wires. However, you can use a voltmeter to check the fixtures for any voltage surges.

If you use a circuit breaker, you will not be shocked. This is the best way to prevent hazards.

Outdated Outlets

Another way you can get electric shock is through worn sockets and switches. The two-prong outlets don’t have a third prong for grounding wire. In an unstable electric current, the ground wire provides safety. It allows the current to flow to the ground instead of electrocuting you.

Electricity Touching Water

Water and electrical wires are a terrible combination. If your hands are wet or, for some reason, the electrical components become moist, there is a high chance of electric shocks. The water is highly conductive. This usually can pose a problem if you replace or install LED underwater lights or LED fountain lights. Make sure the pond is dry before installation.

Mishandling Electricity

Electricity is dangerous to mess with. Always follow safety protocols and preventive measures before dealing with the wires and fixtures. The best way is to ask for an expert electrician to handle your LEDs. Keep in mind the following tips to avoid any hazards:

- Make sure your hands are completely dry while handling electric outlets and LED fixtures.

- Always use Personal Protective Equipment such as insulating gloves and aprons. Better safe than sorry!

- Stay away from the live wires. Please don’t touch them in any case.

- Keep the outlets away from the reach of children. Instead, cover them with plastic cases.

- Keep the fixture area dry and away from any water source. If you are handling the LED underwater lights and fountains, make sure the place is totally dry.

- Always consult professionals.

Why Do LEDs Explode?

Let’s learn what can cause an LED luminaire to explode. This will help you gain a deeper insight into how LEDs work and, hence, prevent such hazards in the future.

Two most common causes of an LED exploding are electrical and thermal stresses.

Electrical Stresses

The electrical components and LED fixtures work on a small voltage, such as 2 or 4 V. However, the LEDs used in your projects are connected to the main voltage of 120 V in most areas. LEDs use capacitors to drop the voltage. If you are using a faulty and low-quality capacitor, it can get overstressed and cause problems.

In some cases, due to voltage fluctuations, the capacitor may break down and let the full current flow through the LED. It will take only a fraction of a second for the LED to burst.

This scenario is called electrical over-stress, and the main cause is the bad or faulty capacitor used in the LED fixture.

Thermal Stresses

Thermal stress can build up in the LED components if there are no proper heat sinks and heat dissipation systems in the bulbs. The heat accumulation causes thermal expansion in the internal components of the LEDs, which creates structural stresses. The expanded components push against the casing and eventually break.

There will be sudden noise, and bits and pieces of the LED fixture will fly across the room. To avoid such problems, always choose high-quality bulbs with proper heat sinks inside them.

LEDs Exploding in Enclosed Fixtures

LEDs in an enclosed fixture are usually used underwater to prevent water from getting in and causing malfunctioning. Do LEDs explode in an enclosed fixture? Yes, they do. This happens mostly because of heat accumulation and thermal stresses. Since there is no outlet for heat in enclosed fixtures, the heat builds up inside and loses efficiency over time.

This problem can be rectified by buying LED fixtures that are enclosed fixture-rated. Moreover, high-quality LEDs have a heat dissipation system, significantly reducing heat accumulation. The fixture remains relatively cooler, and the chances of malfunction decrease.

Another option is to use integrated LED fixtures.

Loose Socket Connections

Sometimes the loose socket connections can cause a spark that can ignite a fire or cause an explosion. A loose connection means that the electrons cannot find a straight path to flow, so they will start jumping from one point to another. This, in turn, creates a lot of heat in the region. And as said earlier, heat stress can cause the bulb to explode.

Lack Of Insulation

A low-quality bulb will not have sufficient insulation at the bulb’s base, which will cause malfunctioning. This causes the metal base of the lamps to melt due to the high heat accumulation of electrical stresses.

Mismatched Voltages

LEDs come with certain wattage ratings. And LED fixtures are designed to work with matching wattages. If the wattage doesn’t match, the fixture can overheat, causing the bulb to explode. You can see the bulb label and check the wattage.

Electrical overstress (EOS) is the major cause of LED dysfunction. The sudden excessive current or voltage can severely damage the LED chip structure. EOS can occur due to internal and external factors such as the working environment, harsh conditions, impacts, human interaction, low-quality parts, or mismatched voltage and currents.

You should know that EOS doesn’t usually cause sudden damage. Instead, it causes micro damages that accumulate over time, and after several working hours, the LEDs stop working.

The Cause of Fire

LEDs themselves rarely cause wire. However, the electrical wires and internal circuits can malfunction and cause a fire. LEDs do not produce the kind of heat that can ignite fires.

Is it Dangerous for LEDs to Dim with Time?

You must notice that your LEDs will start to lose brightness and go dim after some time of installation. This can cause internal malfunction and result in hazardous events such as explosions and electric shocks. Here are a few causes of LEDs losing their shine over time:

Circuit Overload

If you notice LEDs flickering over time, you turn them on; there is a high possibility of the electric circuit being overloaded with heavy appliances. Make sure your connection is separated from the heavy appliances. You’ll see your LEDs dimming and becoming dull because they are not getting a full power supply.

Overloading can cause explosions and electric shocks. Rectify it as soon as you notice flickering.

Grid Problem

Sometimes, due to the overwhelmingly high electricity demand, the grid faces problems. It can be due to weather conditions or the malfunctioning of the transformer.

Lamp Life Has Exceeded

If your bulb is acting up, your lamp may have exceeded its time. You better get it replaced by a newer and high-quality light. Old lamp fixtures and sockets have worn-out wiring and melted components that can be dangerous.

Safety Symbols

We have listed some safety symbols that you may find on the labels of your LED bulbs and fixtures. Knowing what each symbol represents is important for selecting an LED that is best for your application.

This is the ENEC symbol (European Norms Electrician Certificate). The VDE sign indicates that the luminaire and the components are certified by the “VDE Institute for Testing and Certification.”

This symbol indicates that the recessed luminaire is not suitable for installing in the ceiling or walls made of flammable materials.

This symbol indicates that the surface-mounted luminaires are not suitable for installing ceilings or walls made of flammable materials.

The CE symbol indicates that the manufacturer’s product conforms with the European Union.

The CE symbols with the numbers indicate that the inspection bodies check the product following the guidelines.

This symbol indicates that the luminaire is permissible to operate at the mentioned ambient temperature.

This symbol indicates that the luminaire should be kept away from thermally insulating materials.

Conclusion

The electrical classes of luminaires indicate which is best suited for which application. Usually, LEDs are Class III luminaries that provide the highest safety and protection from electric shock. Class 0 luminaries find their application in rare regions. Class I and II luminaires are also seen widely in lighting projects.

It is essential to know the protection levels that luminaries provide. In this detailed guide, we have also mentioned the possible ways you can protect yourself from being electrocuted, including how and when LEDs can give an electric shock or explode.

Always consult an expert when handling LED fixtures. Also, remember to use protective equipment when handling electrical components, especially when installing, maintaining, and replacing LED bulbs.

Contact RC Lighting for more information!